Gasification station technology

The liquefied gas is delivered by a cryogenic tanker to the storage tank at the Customer’s gasification station. Here, under the pressure of the gas cushion of the tank, the liquid is fed to the atmospheric evaporator, where it evaporates at ambient temperature – gasification. The gas pressure in the system is set to the value requested by the recipient and can range from 1.0 to 36.0 bar depending on the type of tank used.

The set includes one or two selected evaporators, depending on the operating conditions, e.g. continuous consumption.

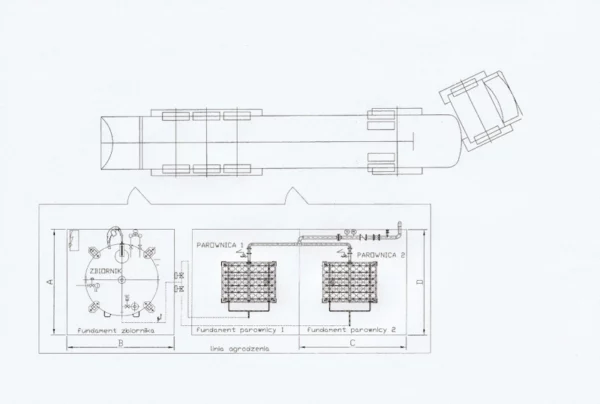

Location of the gasification station

The above figure illustrates an exemplary arrangement of devices on the premises of the gasification station. When positioning the station, attention should be paid to allowing the tanker to reach the tank at a distance of approx. 3.0 m

Dimensions A, B, C and D determine the size of the foundations, which depend on the type of tank and evaporators used.

Gasification stations, which are an integral part of technological installations located in the production building, can be located in the immediate vicinity of the building (by the wall) and treated together with it as one facility, as long as distances from neighboring buildings are maintained.

General requirements

The facility must be built according to the Building Permit Design. It is necessary to provide access to the station for cryogenic tankers, assuming that the tanker should not reverse when entering the station.

In the area of the gasification station, lighting should be installed to enable loading the storage tank in the evening and night. In addition, a 380/220V electrical switchgear should be installed equipped with a 5-pin 380V 63A socket and two 220V sockets

Storage tanks do not require additional lightning arresters, while both tanks and evaporators should be connected to the earthing system, protecting them against atmospheric discharges and static electricity.

The location of the liquid atmospheric gases gasification station must comply with the provisions of the construction law, environmental protection regulations, requirements of the Technical Inspection, fire protection and health and safety regulations. This involves applying to the city or commune office, competent for the location of the station, for the conditions of development and land development.

The possibility of placing the tank and the location of the gasification station will always be decided by the designer adapting a typical gasification station design and developing a plot or land development plan, based on soil data and data of the equipment supplier (companies from the technical gases industry).

The type and size of the storage tank and the evaporator are determined by the gas supplier according to the expected consumption, the required pressure in the customer’s installation and assuming a 20% content reserve in the tank.

Gasification system piping can be made by welding asthenitic steel pipes or by brazing Cu pipes.

Gas oxygen pipelines with a diameter of DN>25 due to the type of medium (gas from group 1, with oxidizing properties) and its pressure PS>0.5 bar are subject to conformity assessment ( Directive 2014/68/EU) for CE marking according to the Regulation of the Minister of Development of 11 July 2016 on the requirements for pressure equipment and pressure equipment assemblies (consolidated text: Journal of Laws of 2019, item 211),

Pipelines of other atmospheric gases (group 2, inert gases) with a diameter of DN>32 require verification as to the need to assess conformity for CE marking. Type of performance requirements and conformity assessment module and CE marking according to Directive 2014/68/EU.