Technical gas pipelines are technological pipelines classified as pressure equipment.

Technological pipelines must meet the safety requirements for pressure equipment included in the PED Directive 2014/68/EU. Oxygen piping systems (group 1 according to §11 of the regulation of the council of ministers implementing the pressure directive PED 21014/68/EU) and nitrogen, argon, welding mixtures (group 2 according to §10 of the regulation of the council of ministers implementing the PED 21014/68/EU directive) are subject to conformity assessment in the design and manufacturing phase and are not subject to UDT acceptance in the operation phase. The manufacturing process of the pressure equipment must be subject to appropriate conformity assessment procedures.

After classifying the pipeline into the appropriate category, the execution of pipelines is carried out according to the corresponding PED procedure.

The legal bases are as follows:

- PED Directive 2014/68/EU implemented by the Regulation of the Minister of Development of 11 July 2016 (DU2019, item 211),

- regulation of the council of ministers of 07.12.2012 on the types of devices subject to technical supervision (Journal of Laws of 2012, item 1468), §1, section 1).

Flammable gas installations, requiring approval for operation due to the operating parameters by the Office of Technical Inspection (UDT), are designed and constructed under the supervision of the Notified Body.

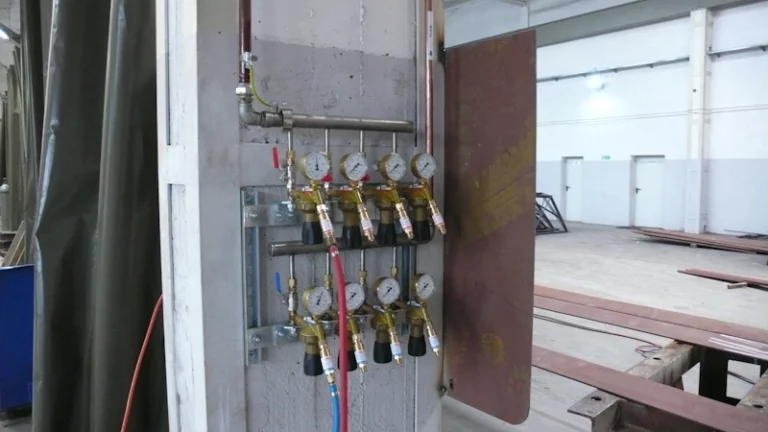

The route of the pipelines is set out during assembly according to the assumptions adopted in the installation design, and in consultation with the hall user in accordance with the principles of installation of copper or steel pipelines.

Installation works end with a pneumatic pressure test at a test pressure of 1.43 x max. operating pressure of the installation and a pneumatic leak test at a test pressure equal to the maximum operating pressure of the installation.

The course of the test and its result is confirmed by an appropriate protocol signed by the contractor and the user of the installation.

Propane systems

Propane systems are used to power various types of industrial equipment and machines. Propane is a liquefied petroleum gas that is easy to store and transport, making it an ideal fuel for many industrial applications. When designing and constructing propane systems, many factors should be taken into account, such as:

- Propane demand: Determine how much propane will be needed to power industrial equipment and machinery

- Security: Propane installations must be designed and built in a way that is safe for users