Connecting the laser device to power sources (liquid nitrogen-oxygen gasification stations or a bundle with cylinders) takes place after a cleanliness test carried out in the presence of a service technician and a representative of the investor.

Installation of copper pipelines of CU-DHP type is carried out in the technology of soldering with silver solder without any Teflon connections. Only after the approval of the service technician, the machine is connected with a flexible cable prepared to work in an atmosphere of pure oxygen to the built installation.

At the request of the investor, the purity of the gas at the entrance to the cutter can be confirmed by a gas purity analysis performed with a particle analyzer – met ONE 3400 plus.

Our many years of experience in the construction of the cutting gas system of laser cutters allows us to conclude that this way of building the system is the most reliable and ensures long-term operation of the machine without any failures. Over the past 20 years, Centrogaz has installed 1314 laser devices throughout Poland with 100% efficiency. During these years, we have not recorded any complaints, which is the most important thing in our industry. We connect machines of such companies as: Eagl, Trumpf, Bystronic, Mazak, BLM, Amada, and others.

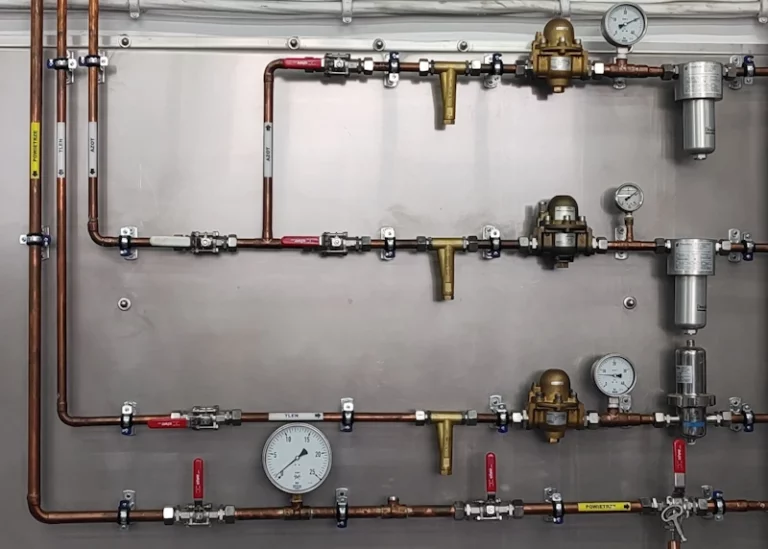

Components of the cutting gas supply system

The gas pipes, connections and regulators used must meet the high gas purity requirements.

Copper pipe gas tubing

Use gas pipes made of copper pipes in a special oil-free and lubricant-free design.

- material No. 2.0090 according to DIN 1787

- tolerances according to DIN 59753

- mechanical properties according to DIN 17671

until the moment of use closed at the ends with plastic caps suitable for medical and technical gases

Gas pipes made of stainless steel pipes

Alternatively, stainless steel gas pipes in a special oil-free and lubricant-free design may be used.

- material No. 1.4404 or 1.4435

- tolerances according to DIN 1127 / ISO 5252

along the entire length permanently marked with plastic caps at the ends suitable for medical and technical gases, joints should be welded

Oxygen systems

Oxygen systems are an important element of many industries. They provide oxygen, which is necessary for many technological processes. When designing and constructing oxygen systems, many factors must be taken into account to ensure their proper operation and the safety of users.

Nitrogen systems

Nitrogen systems are used to produce nitrogen, which is an inert, non-flammable and non-toxic gas. It is widely used in many industries, including food, chemical and pharmaceutical industries. When designing and constructing nitrogen systems, many factors should be taken into account, such as:

- Nitrogen demand: Determine how much nitrogen will be needed for a given technological process

- Nitrogen quality: Determine what nitrogen purity is required for a given process

- Security: Nitrogen installations must be designed and built in a way that is safe for users